Korloy Inserts

Product Details:

- Cutting Speed Up to 800 m/min (application dependent)

- Tool Type Turning/Milling Insert

- Spindle Speed Up to 10,000 rpm (application dependent)

- Noise Level Low (dependent on machine)

- Application Metal Cutting, Turning, Milling

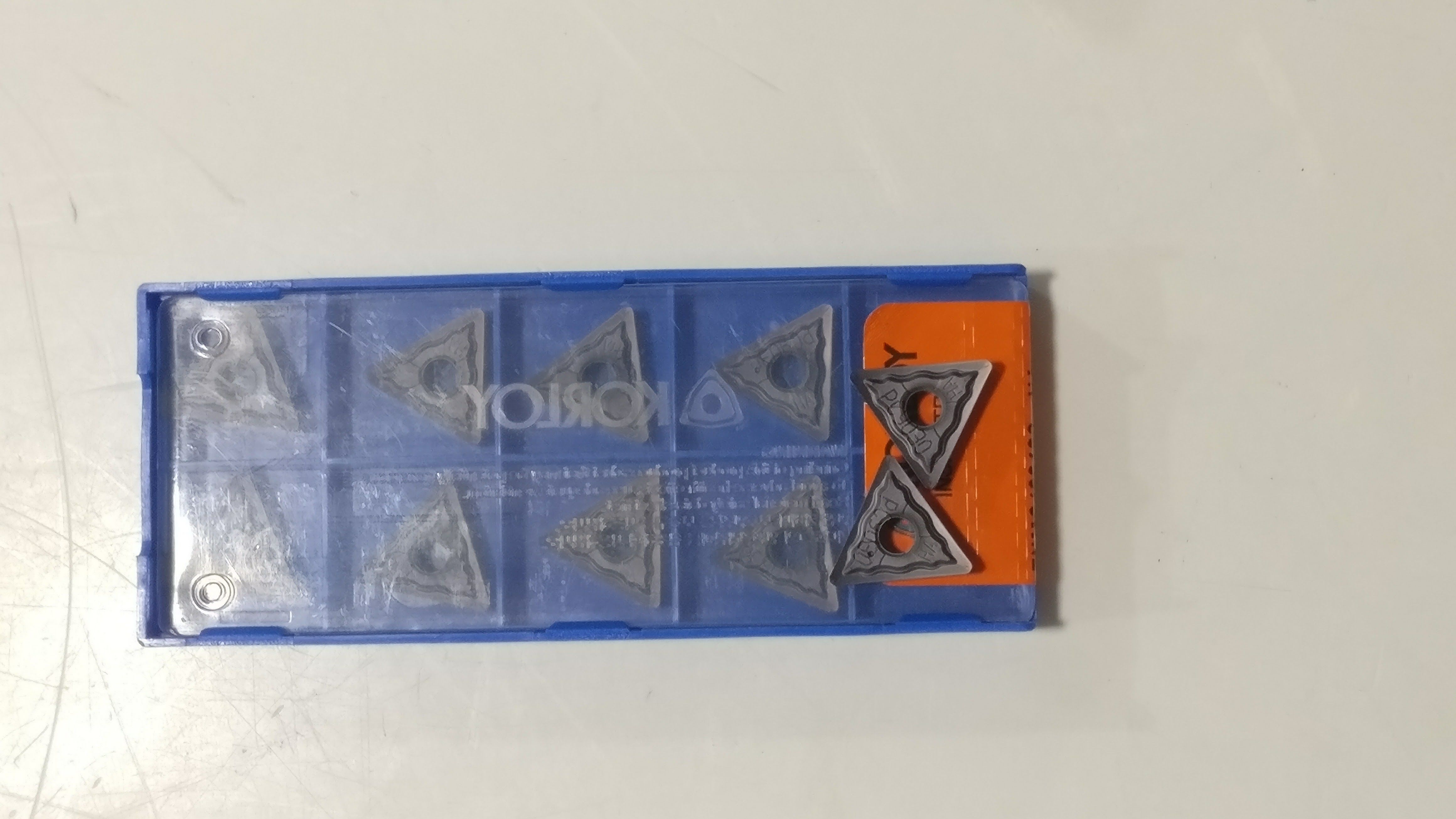

- Material Carbide

- Computerized No

- Click to view more

Korloy Inserts Price And Quantity

- 1 Piece

- 165.00 INR

Korloy Inserts Product Specifications

- Carbide

- Metallic Gray / Gold (coated)

- No

- Up to 800 m/min (application dependent)

- High precision, long tool life, wear resistance

- 0.01 - 0.05 kg per insert

- Manual

- Varies per model (typical: 12mm x 6mm x 4mm)

- Turning/Milling Insert

- Low (dependent on machine)

- Up to 10,000 rpm (application dependent)

- Standard industrial cutting performance

- Metal Cutting, Turning, Milling

Korloy Inserts Trade Information

- Cash on Delivery (COD), Cash in Advance (CID), Cash Advance (CA)

- 300 Piece Per Day

- 2 Days

- All India

Product Description

Korloy Inserts

Korloy has revolutionized the carbide industry with it's high calibre and unquestionable performance making it one of the most successful companies in the world.

We are proud to be associated with such a brand by their certificate of authorisation drawn to us in dealing their products on a national and international level. We are stockists of all Korloy products, ready to cater to all your needs so that you don't need to look elsewhere! As authorised dealers we receive significant benefits from the company itself which we generously pass down to our clients in form of low rates and quick supply.

Our major and best selling turning inserts include TNMG 16, CNMG 12, CNMG 19, DNMG 15, SNMG 19, VNMG 16, VNMG 12, VBMT 16, WNMG 08 & many more available in all grades and geometries mainly comprising of PC 9030, NC 3120, NC 6210, NC 3010, NC 6110 etc.

We have large quantities of boring inserts of CCMT 06, CCMT 09, TCMT 11 & TCMT 16T as they are our fastest selling items too.

We also have a variety of grooving inserts as the MGMN series of 2.00, 2.50, 3.00 & 4.00 available in grades PC 9030, NC 3120, NC 3020. Alongwith grooving, we have milling inserts in SDXT 09M405, SDXT 130508, APMT 1604, APMT 11T3PDSR & many more in the most efficient grades 9030, 5300, 3500, 8110, 6315.

Versatile Cutting for Industrial Demands

Korloy inserts, made from premium carbide and enhanced with PVD/CVD coatings, accommodate various cutting needs in turning and milling operations. Their compatibility with standard tool holders and availability in different grades and geometries make them a preferred choice for industries requiring reliability and precision.

Engineered for Longevity and Efficiency

These inserts feature superb heat resistance, smooth surface finishes, and are available in sharp, chamfered, or honed edge preparations. Their metallic gray or gold coated appearance and adherence to ISO 1832 ensure they meet rigorous industrial standards, offering both durability and consistent performance.

FAQs of Korloy Inserts:

Q: How do I choose the right Korloy insert geometry and edge preparation for my application?

A: Select the insert geometry (CNMG, TNMG, SNMG, etc.) based on your machining operationturning or milling. The edge preparation depends on the desired surface finish and material; sharp for fine finishes, chamfered or honed for heavy-duty or interrupted cuts.Q: What are the benefits of PVD/CVD coating on Korloy inserts?

A: PVD and CVD coatings enhance the inserts wear and heat resistance, extend tool life, and optimize performance by reducing friction and maintaining a smooth surface during high-speed operations.Q: Where can I use Korloy carbide inserts?

A: These inserts are suitable for a variety of industrial metal cutting, turning, and milling operations and are compatible with standard tool holders used in manufacturing plants, machine shops, and industrial workshops.Q: When should I replace my Korloy insert?

A: Replace the insert when you notice excessive wear, loss of surface finish quality, increased vibration, or a rise in cutting forces. Timely replacement ensures consistent performance and avoids tool breakage.Q: What is the process for installing Korloy inserts into a tool holder?

A: Ensure the machine is powered off. Securely place the correct insert into the compatible tool holder, ensuring proper alignment with the relief angle (typically 0, 7, or 15 depending on insert type) before tightening.Q: What is the maximum spindle speed and cutting speed for these inserts?

A: Korloy inserts can operate at spindle speeds up to 10,000 rpm and cutting speeds up to 800 m/min, depending on the application and material being machined.Q: What main benefits do users gain from using Korloy inserts?

A: Users benefit from high precision, long tool life, enhanced heat resistance, consistent surface finish, and the ability to handle demanding cutting conditions with reduced downtime due to wear.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+